2025-T3 Vs 2025-T3511

2025-T3 Vs 2025-T3511. Aluminium 2025 is a widely used aerospace alloy for applications requiring high strength to weight ratio. This specification covers an aluminum alloy in.

They share alloy composition and many physical properties, but develop different mechanical properties as a result of different processing. Temper designations for aluminum alloys are as follows:

They Share Alloy Composition And Many.

It is used in applications requiring high strength to.

Available From Stock In All Forms:

They share alloy composition and many.

Aviation Aluminum Profiles Can Be Used For The Keel, Beam And Rib Structure Of The Fuselage, Which Bear The Weight.

Images References :

Source: www.researchgate.net

Source: www.researchgate.net

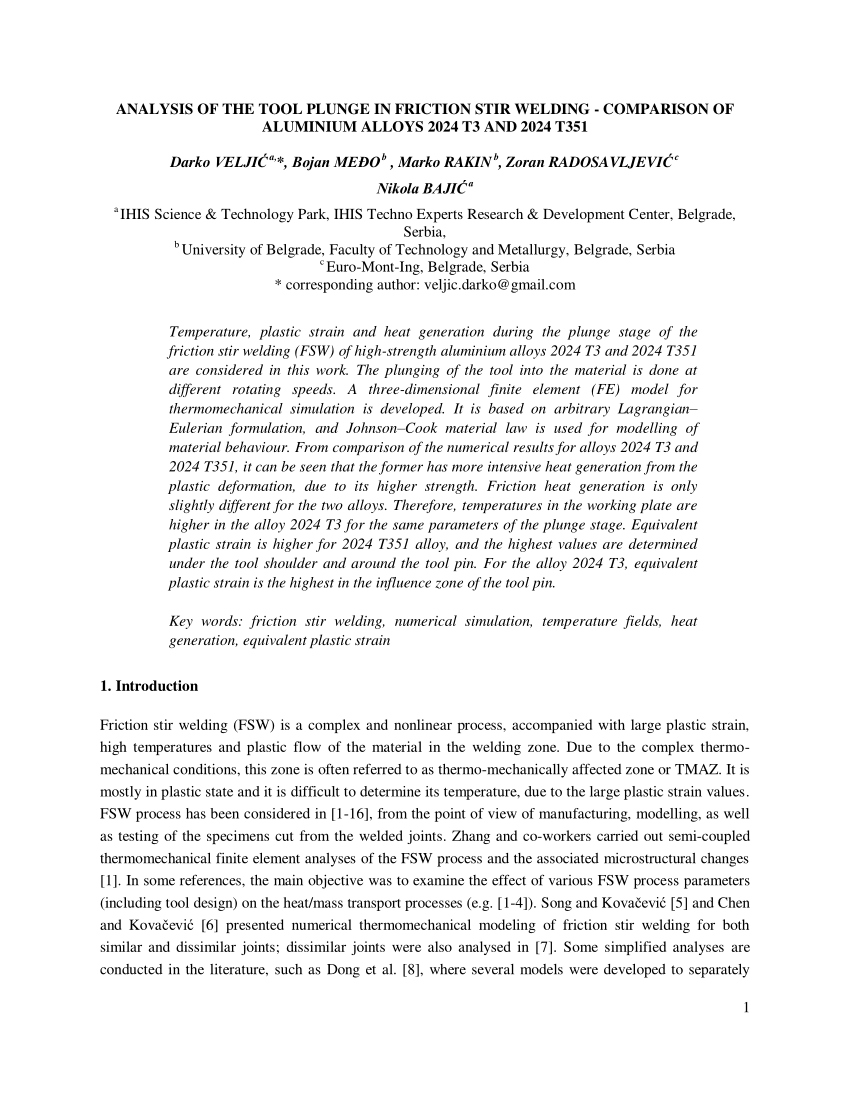

(PDF) Analysis of the tool plunge in friction stir welding comparison, Cooled from an elevated temperature shaping process and naturally aged to a substantially stable condition. This specification covers an aluminum alloy in.

Source: www.researchgate.net

Source: www.researchgate.net

JohnsonCook Material Model of Aluminum 2025T3/T351 Download, They share alloy composition and many. Applications | specifications | related videos | mechanical and chemical data | tolerances.

Source: www.studypool.com

Source: www.studypool.com

SOLUTION Analysis of the tool plunge in friction stir welding, They have a very high 99% of their average alloy composition in common. Cooled from an elevated temperature shaping process and naturally aged to a substantially stable condition.

Source: www.researchgate.net

Source: www.researchgate.net

JohnsonCook Material Model of Aluminum 2025T3/T351 Download, 2025t3 alclad aluminum sheet aluminum alloy sheet is sold in the thicknesses and sheet sizes shown in the table. 2025 aluminium alloy sheet is an aluminium alloy, with copper as the primary alloying element.

Source: www.oceanproperty.co.th

Source: www.oceanproperty.co.th

Aluminum 2025T3 StressStrain And Fatigue Life Data EVOCD, 59 OFF, 2025 aluminum is one of the strongest aluminum alloys, though. Applications | specifications | related videos | mechanical and chemical data | tolerances.

Source: www.scribd.com

Source: www.scribd.com

aluminium2025t42025t351 Strength Of Materials Hardness, 2025 aluminium alloy sheet is an aluminium alloy, with copper as the primary alloying element. They share alloy composition and many.

Source: www.amazon.com

Source: www.amazon.com

LaDeau Aluminum 2025/T3511 MilSpec Complete Continuous Hinge with, They share alloy composition and many. They share alloy composition and many physical properties, but develop different mechanical properties as a result of different processing.

Source: www.mdpi.com

Source: www.mdpi.com

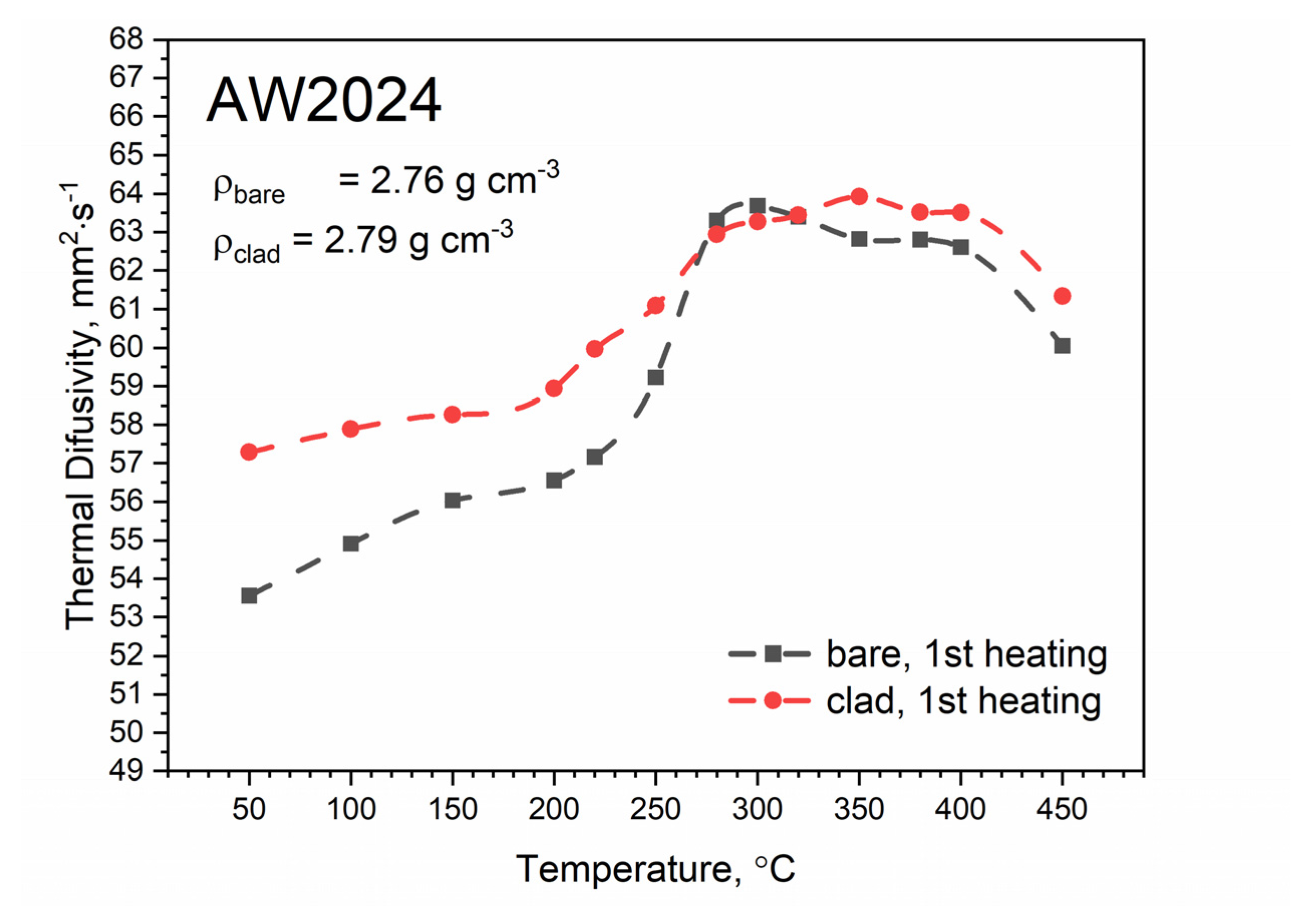

Materials Free FullText Investigation of Thermophysical Properties, Available from stock in all forms: Aluminium 2025 is a widely used aerospace alloy for applications requiring high strength to weight ratio.

Source: www.smithsmro.com

Source: www.smithsmro.com

2025 Aluminium 2025 T3511, Aluminium 2025 is a widely used aerospace alloy for applications requiring high strength to weight ratio. Aviation aluminum profiles can be used for the keel, beam and rib structure of the fuselage, which bear the weight.

2025 Aluminum Square Bar T3 T3511 T8 T8511 FONNOV, Some improvements are realized when 2025 alloy is produced in these. Minimum sheet size available is 2' x 4'.

Available From Stock In All Forms:

Cooled from an elevated temperature shaping process and naturally aged to a substantially stable condition.

Aluminium 2025 Is A Widely Used Aerospace Alloy For Applications Requiring High Strength To Weight Ratio.

Temper designations for aluminum alloys are as follows: